| For maintenance of electric and electronic equipment | |

| 1. Substations For monitoring irregular temperature of the main terminal connecting parts of electric power equipment (a) Outside of radical square (LS) fixed contact maker (b) Outside of disconnecting switch (DS) fixed contact maker or movable contact maker (c) Clamping part of oil circuit breaker (OCB) terminal (d) Clamping part and body of transformer (Tr) terminal (e) Clamping part of silicone condensor (SC) terminal (f) Clamping part of current transformer (CT) terminal For monitoring irregular temperature of ultra high pressure substations. |

4. Rotating Electrical Equipment For monitoring the temperature of motors For monitoring the temperature of rotating parts (a) Fixed winding and insulated rotor winding (b) Armature coil with commutator (c) Resistance field winding and compensating winding (d) Exposed phase field winding (e) Commutators and slip rings (f) Bearings |

| 2. Distributors (a) For monitoring irregular temperature of bus inside cubicle, CB disconnecting parts, contact parts inside MBB, etc. (b) For monitoring load of transformers on telegraph poles (c) For monitoring irregular temperature of terminal parts or blade parts of electric power condensors, resistors for arc-suppressing resistors and breakers |

5. Electronic Components (a) Circuit parts For monitoring the temperature of condensors, resistors, coils, and integrated circuits (b) Vibrating parts For monitoring the temperature of quartz oscillators, mechanical filters, lead selectors, etc. (c) Mechanism Components For monitoring the temperature of magnetic relays, connectors, plugs, jacks and switches (d) Semiconductor parts For monitoring the temperature of transistors, diodes, thyristers and integrated circuits |

| 3. Controllers For monitoring the temperature of electromagnetic switches, electromagnetic contactors, electromagnetic relays, knife switches, high pressure breakers, high pressure load switches, electric power condensers (parallel, high pressure circuit, series), arresters, induction reactors and magnetic amplifiers. |

6. Transmission Equipment (a) For monitoring irregular heat generation of compression sockets and sleeves of jumper wires (b) For monitoring the temperature of terminal fittings for feeder lines, negative feeders, stringing, auxiliary stringing , direct connecting pipes for feeder branches, jumper connecting pipes, branch connecting pipes, feeder ears, connectors and feeder switches. |

|

THERMO LABEL LI Heat evolution checking for coils of communication equipment. |

| For monitoring the temperature of Manufacturing Processes | |

| 1. Mining (a) To monitor the temperature of metal melting furnaces (b) To judge completion of electric copper smelting (c) Heat treatments (d) Bucket conveyors |

3. Electrical, Electronic and Communications Equipment (a) When manufacturing the light bulb (b) To check the life of light bulb (c) To check the rise in temperature inside electric motors (d) To check the rise in temperature of print substrates (e) Heat treatment temperature of duplicating machines (f) To judge the occurence of heating in the event of trouble (g) To monitor the heat temperature of heat contraction tubes for communications cables |

| 2. Automobiles and shipbuilding (a) When painting (b) To check the hardening condition of brake shoe adhesive (c) Dies (d) Inside engine parts (e) To check the preheating temperature when welding |

4. Food (a) Level gauge for brewing tanks (b) To check the heat treatment temperature when brewing (c) To check the sterilization treatment of retort foods (d) When making bread (e) To check the temperature rise during transportation |

| 5. Textiles During printing |

|

|

|

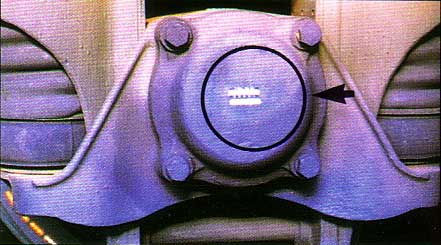

| THERMO LABEL E Verification of axle temperature |

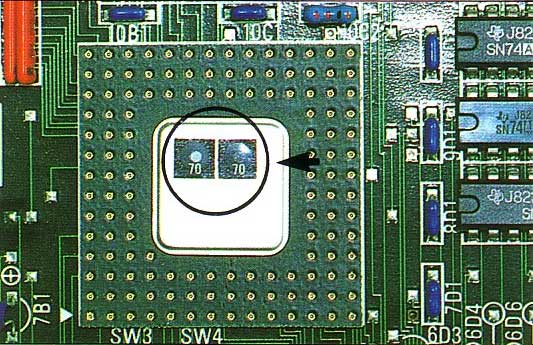

THERMO LABEL 1K Temperature checking for electronic parts |